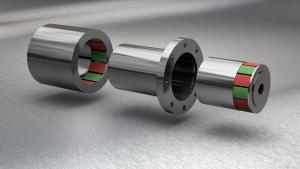

Magnetic Coupling

Magnetic Coupling

Magnetic coupling transmits rotational power (torque) between shafts without physical contact, using magnetic attraction and repulsion through an air gap, enabling sealed systems for corrosive liquids, preventing misalignment issues, and offering overload protection by slipping when torque limits are exceeded. With well over 1,000 magnet configurations, we are able to find the perfect solution for the diverse applications of our customers.

Advantages of magnetic coupling:

- ATEX certification

- Ensure a hermetically sealed torque transmission

- leakage, wear and maintenance free

- Designed for high torques up to 25,000Nm

- Resistant against aggressive media

- High quality, made in Germany

Torque

- Standard: 1 – 1,200 Nm

- Customer-specific: 0.1 up to 25,000 Nm

Materials

Optimally matched to the various media, the wetted parts of the magnetic coupling are made of different materials:

- Standard: 1.4571 and 2.4610 (Hastelloy C-4)

- Stainless steel: 1.4301, 1.4401, 1.4404, 1.4435, 1.4539, 1.4980

- Hastelloy: 2.4602 (C 22), 2.4819 (C 276)

- Titanium: 3.7165 (Grade 5), 3.7035 (Grade 2), Beta C/Grade 19, Ti 6 2 4 6

Plastic: PTFE, PFA, TFM, PVDF - Many other special materials on request.

Application Areas:

– Autoclaves

– Chemical Industry

– Compressors

– Dosing Technology

– Food Industry

– Hydraulics

– Industrial Furnaces

– Laboratory Industry

– Petrochemistry

– Pharmaceutical Industry

– Process Engineering / Process Industry

– PU Industry / PU Machines

– Ship Industry

– Water Management

Bottom-mounted Agitator Drives

Canisters

Conversion Kit

Magnetic Coupling

Overhead Agitator Drives